What You Should Know About Farming Machinery Modification

From its early days, agriculture has been the backbone of supplying their respective nations with enough food and nutrition to support growth. Today's agricultural technologies have since leapfrogged beyond what our predecessors could imagine, especially with technologies that are developed in the beginning of the 21st century.

Modern farming practices will include farming machinery that has motorized equipment, modified housing for animals and significant reliance on biotechnology for major improvements in agriculture. This has resulted in farmers being able to produce more with significantly less effort.

For example - our change of dependency on horse or bull-driven equipment to motorized equipment has saved significant downtime and costs as animals require feeding, rest and care. On the other hand, motorized equipment requires minimal supervision and maintenance.

In this article, let's take a look at the different types of agricultural machinery and their relevant farming machinery modifications, as well as the important aspect of agricultural machinery repair.

Types of Agricultural Machinery

Here are some of the common agricultural machinery you can find in the marketplace today:

1. Plows

Plows can be separated into three distinct categories. The first, moldboard plows, are often used on land that has not been in crop production before. The large wings of the plow are designed to cut into and turn over all of the soil in an area.

Next, the chisel plow has long shanks instead that can turn over soil of up to 12 inches deep. Chisel plowing after applying a soil amendment can incorporate the amendment to 3 to 4 inches.

Lastly, the disk plow cuts into the soil but doesn’t turn it over completely the way a moldboard plow would.

2. Planters

Mechanized planters have been an essential tool for large-scale farmers for decades, and their popularity has not waned since. While they are mostly large, industrial-sized planters, there are forms of handheld planters as well as tractor-pulled planters to allow smaller-scaled farmers to plant more efficiently as well.

As a major step-up to the traditional digging method of using a spade, transplanters allow farmers to transplant their produce onto the ground without the grueling physical demands from the past.

3. Sprayers

As its name suggests, sprayers are a form of agricultural farming machinery that allows the farmer to spray insecticides, pesticides, herbicides, fertilizers and any other products meant to be sprayed on the farm or plants with operational ease and efficiency.

There are, however, various forms of sprayer machines. This ranges from aircraft-based sprayers to simple blower-type sprayers. There are also further distinctions between liquid or powdered insecticides or pesticides that can be sprayed using these machines.

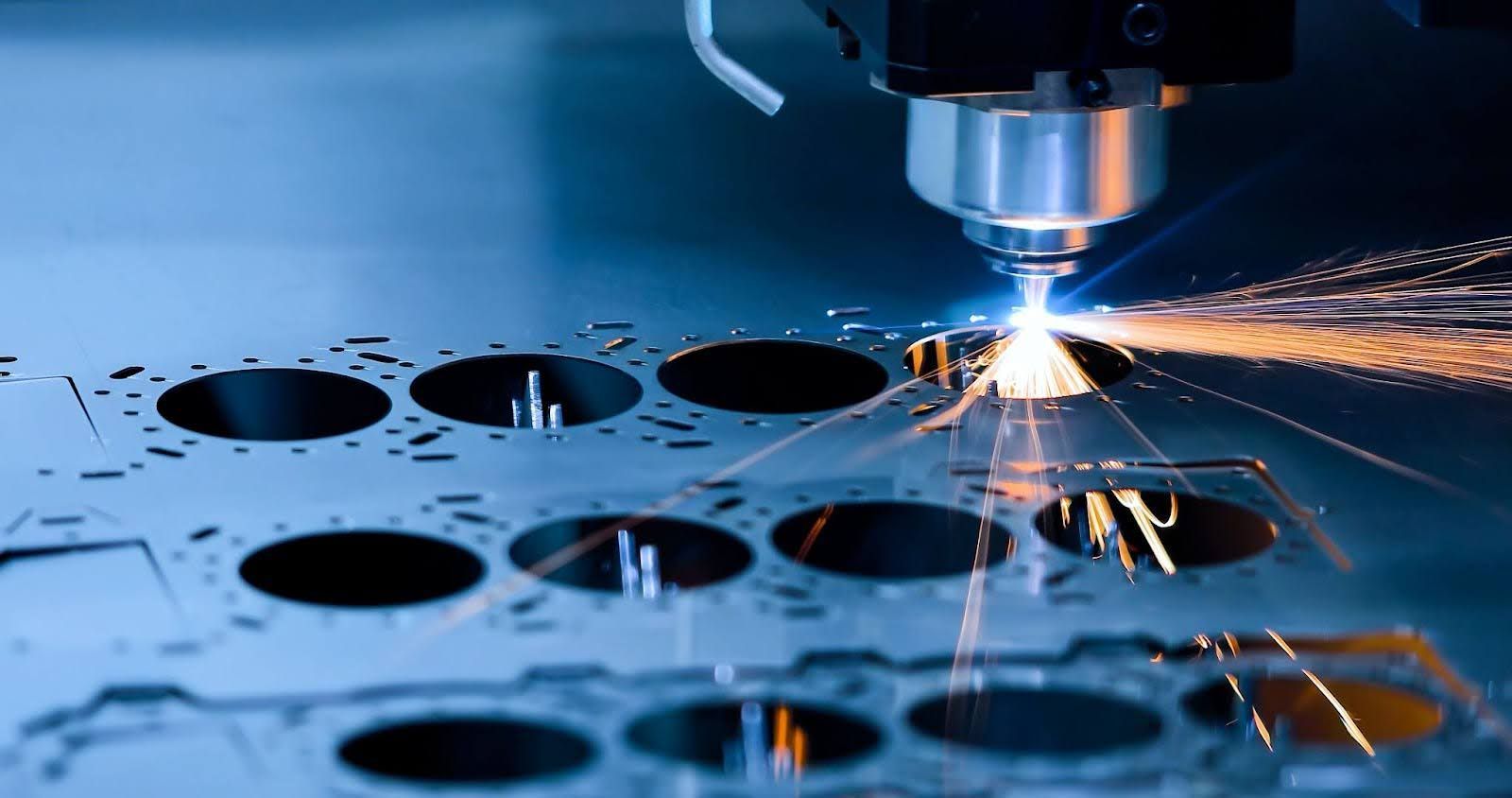

Agricultural Farming Machinery Modification

Ask every farmer out there and you'll come across the practice of farming machinery modification to fit their farming requirements and conditions. While it's a practice that is certainly not new to the industry, the popularity of modifying their farming machinery has become increasingly common as labor costs and resources are ever-increasing.

The reasons for farming machinery modifications are simple - most machinery manufacturers are designed and developed for the most generic form of farms, thus driving many farmers with machinery that is unfit for their specific farming conditions.

As the cost of custom machinery is often too expensive, this results in farming machinery modifications as the way to go.

However, most experts believe that modifying your farming machinery, while benefiting in the short term, might come with their own set of risks.

One of the main concerns is that a poorly executed modification of a piece of machinery often voids its warranties and might result in a larger cost to repair and maintain in the long run.

Apart from warranties, farmers might also unexpectedly face poorly performing machinery, safety issues to the machine operators or simply damaged crops from the modified machinery

Looking for experts to modify your farming machinery? Choong Ngai Engineering can help

With over 19 years of expertise in metal fabrication industry, Choong Ngai Engineering has been helping our happy customers and farmers achieve their maximum potential out of their agricultural farming machines.

Learn more about our services and previous projects on our website. Contact us at +6012-2726971 or email your queries to choonngaiengworks@gmail.com.

CHOONG NGAI ENGINEERING WORKS SDN BHD

is managed by a team of experienced professionals who ensures that our jobs are completed satisfactorily in a timely matter. We prioritise on our clients' needs and believe that our clients are entitled to the best services available.

QUICK LINKS

CONTACT

243A, Jalan 2A, Kampung Baru Subang, 40150 Selangor Darul Ehsan, Malaysia

Choong Ngai Engineering. All Rights Reserved. Website Designed by Heroes Of Digital.