Sheet Metals In Architecture: What To Know and Benefits

Architectural design is not just about aesthetics; it's also about the materials used to make those concepts a reality. In modern architecture, sheet metal, which is frequently disregarded, is crucial and opens up a world of options for designers and builders. The intriguing union of architectural innovation and sheet metal will be explored in detail in this article.

Sheet metal has gained popularity among modern architects because it can be used to build iconic facades and is durable and environmentally friendly. So, let's take a look at the application and benefits of sheet metal fabrication in architecture.

The Various Types Of Sheet Metal Materials Used

Similar to how architectural designs differ, so do the materials used to create them. From the classic beauty of copper to the slick contemporary design of stainless steel, each material has its own combination of physical characteristics and visual attributes.

Here are some examples of sheet metal materials that are being used in the architectural industry.

Stainless steel

In contrast to older materials, stainless steel has become increasingly popular because of its timeless, sophisticated, and pristine look. Its remarkable durability can be attributed to the fact that it is an alloy consisting of various other metals, including:

- Chromium

- Nickel

- Iron

Stainless steel is ideal for window grills, door panels, and other outdoor decorations.

Copper

Copper's original metallic reddish-brown brilliance is what makes it so desirable, but it also delivers an unrivalled elegance for any structure. It can last hundreds of years before oxidising to a permanent vivid green.

In addition to being highly durable, it doesn't rust or break down in bad weather. Furthermore, it is a soft and pliable metal that can be shaped into almost any form. Copper can be used for large showcases, which includes:

- Wall panels

- Roof tiles

- Doors

- Gates

- Window frames

However, this exquisite metal works wonderfully for ornamental details, such as:

- Finials

- Trimmings

- Fittings

Aluminium

Given the wide range of surface treatments and colours, aluminium sheet metal offers an extensive selection of style options. Aluminum's malleability and adaptability allow for intricate detailing in carefully crafted forms.

Its versatility means it can be used for everything from wall panels to indoor and outdoor sconces.

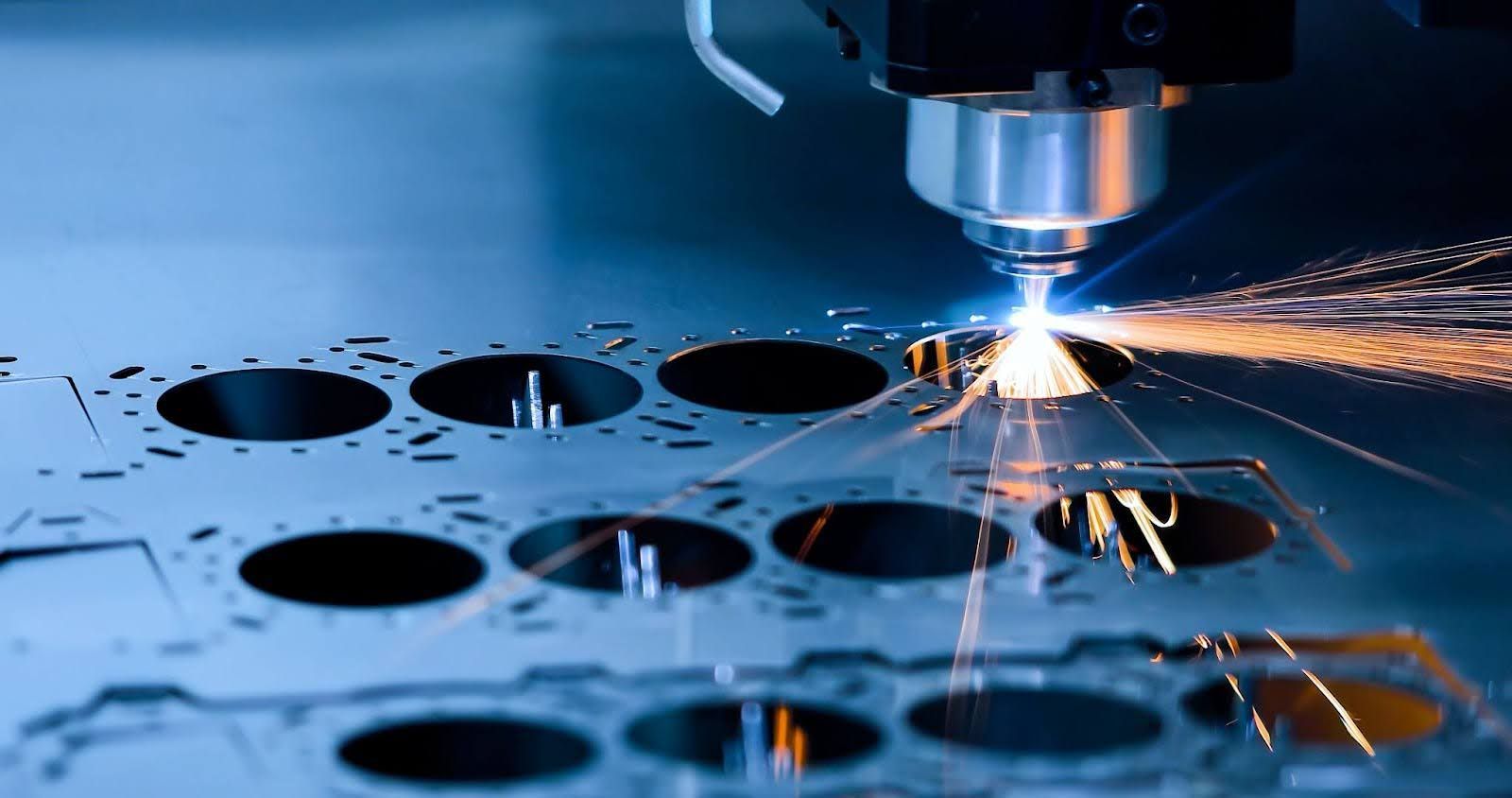

Methods Used To Process The Sheet Metal

The techniques used to work with sheet metal are crucial as architects and builders imagine and create remarkable buildings. These techniques sculpt the materials which shape our cities through complex perforations and precise folding.

Hot rolled steel

In the process of hot rolling steel, it is heated to an incredibly high temperature before being shaped. Since the steel can contract as it cools, the method is simple but lacks the precision of cold rolling.

Cold rolled steel

The process of cold rolling steel transforms steel into a sheet that is remarkably thin but incredibly robust. After that, it goes through the process of being washed and treated. As a result, the steel is soft and pliable so that it can be moulded into any design.

Benefits Of Using Sheet Metal In Architecture

With its reputation for versatility and durability, sheet metal has become a dynamic force in contemporary architectural design. This section will begin with an exploration of the numerous benefits that come with using sheet metal in architectural projects.

Durability

Sheet metal has earned a reputation for withstanding a wide range of climates, elements, and other environmental factors. It has been chemically treated to be UV and corrosion-resistant, making it ideal for outdoor projects.

Versatility

Sheet metal comes in a wide variety of styles and can be used in many different construction applications. In the past, copper and brass sheet metal were used to decorate things like roofs and trims. These days, there are a lot of modern materials like:

- Aluminium

- Zinc

- Stainless steel

The degree of accuracy in the shapes and cuts will mostly depend on the material selection.

Aesthetically pleasing

Remarkable aesthetics can be produced with ornamental sheet metal in an array of techniques based on factors such as:

- Material

- Location

- Design

Among the notable uses of sheet metal in history and the present are:

- Roof tiles

- Domes

- Steeples

- Cupolas

- Roof finials

- Statues

- Urns

- Balustrades

- Trims

The Various Elements That Use Sheet Metal

To create the spaces we live in, architecture is more than simply the structures themselves. As architects and designers learn more about what sheet metal can do, these parts make their work more functional and give it artistic and structural depth.

Windows And Doors

Perforated or flattened expanded metal is used in open-concept doors and windows to provide privacy while allowing natural light to pass through. An additional option for solid door or window shutters is decorative sheet metal in a stamped or corrugated design.

Walls And Dividers

Metal sheets are attached directly to exterior or interior walls to produce various looks and styles. The combination of its colour, gloss, and reflecting characteristics makes for a stunning aesthetic statement and a unique final result.

Many dividers and walls also feature corrugated or perforated designs to improve functionality and enhance the space.

Gates And Fences

Fences and gates are useful features for many properties. By replacing standard metal rods with perforated metal sheets, you can achieve a sophisticated exterior appearance. Soundproofing and privacy are two extra benefits of using sheet metal for fences and gates.

Embrace The Uniqueness And Versatility Of Sheet Metal Fabrication

Not only have sheet metals found a place in buildings with famous facades but also in buildings with critical structural parts and intricate interior details. By influencing the structures that characterise our towns and societies, they have evolved into an essential part of modern architecture.

Sheet metals are expected to be even more important in influencing how our built environment is shaped as architects and designers continue to push the limits of what is possible. These materials not only combine form and function, but they also promote sustainable and long-term use.

Looking for a quality sheet metal fabricator in Malaysia? Choose Choong Ngai Engineering!

So, if you're looking for

sheet metal fabrication in Malaysia, visit us at

Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for.

Call us now!

CHOONG NGAI ENGINEERING WORKS SDN BHD

is managed by a team of experienced professionals who ensures that our jobs are completed satisfactorily in a timely matter. We prioritise on our clients' needs and believe that our clients are entitled to the best services available.

QUICK LINKS

CONTACT

243A, Jalan 2A, Kampung Baru Subang, 40150 Selangor Darul Ehsan, Malaysia

Choong Ngai Engineering. All Rights Reserved. Website Designed by Heroes Of Digital.