7 Industries That Benefit From Metal Stamping

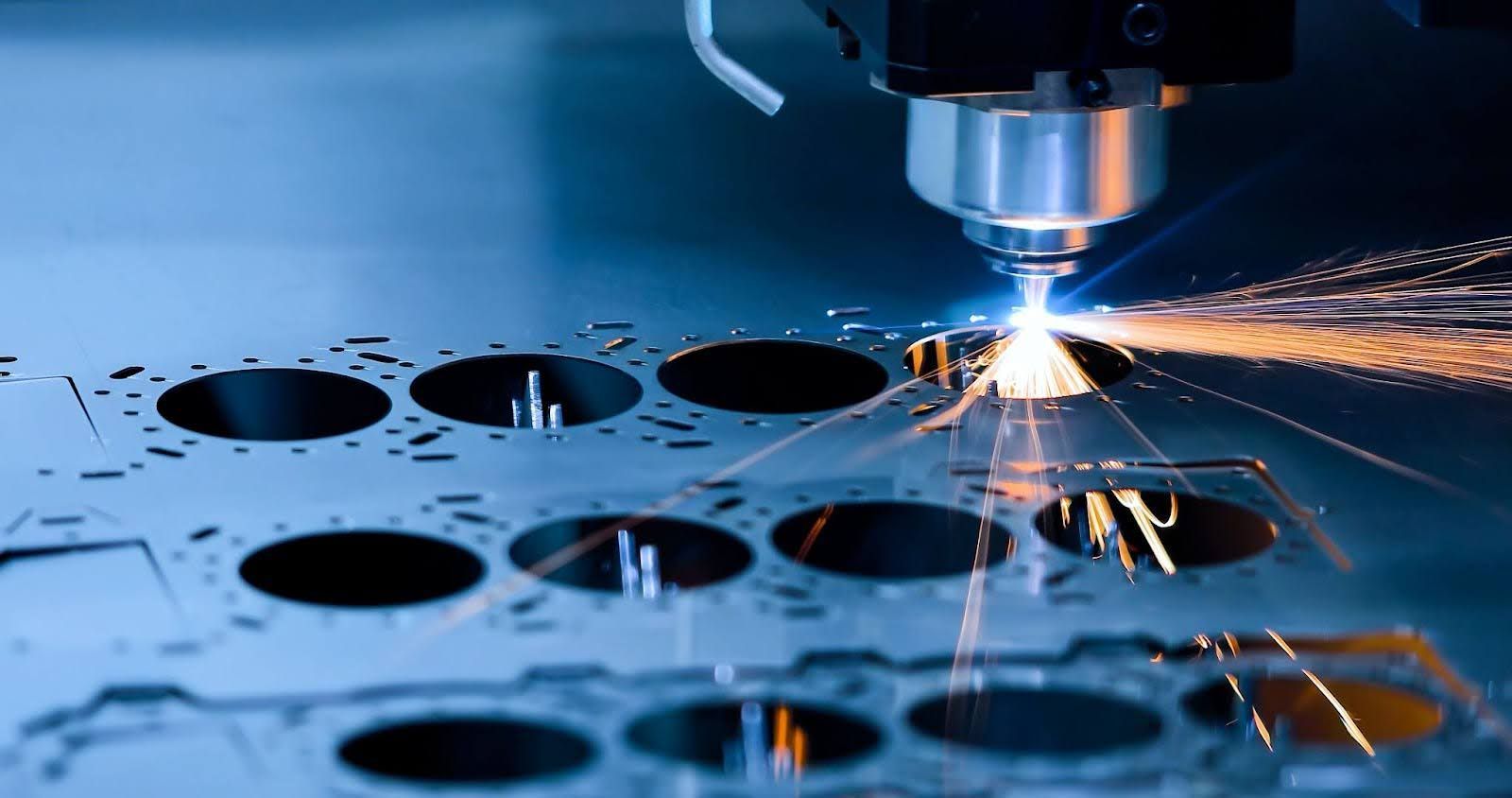

The ancient art of metal stamping is essential to contemporary industry and goes beyond mere craftsmanship. Metal stamping discreetly moulds everything from the modest pieces of your home appliances to the vital components of cars. In this piece, we'll explore some of the most critical industries for metal stamping.

From aerospace to electronics, medical devices to the automotive industry, we will examine how the precision and efficacy of metal stamping make it indispensable.

Follow along as we reveal the rich tapestry of businesses that profit from metal shaping, whether you are an insider, an aspiring engineer, or just curious about the wonders of metal shaping.

Aerospace

To comply with regulatory body standards, the aircraft industry needs strict quality controls and continuous documentation. From concept to production, the engineering process for metal stamping is meticulously planned and executed, yielding precise results. With metal stamping, the cost-benefit ratio is maintained while enabling real-time measurements, visibility, and control over all safety measures. The end product is a well-designed procedure that will withstand stringent quality assurance measures.

Metal stamping engineers must ensure that production and control procedures in this sector are documented per the latest standards and laws. They must implement quality control procedures to provide the best traceable part possible.

Military And Defence

Military and defence contractors share the same emphasis on deadlines and costs as the public transport industry. Defence contractors also operate in a field where accuracy, durability, and reliability are essential.

Metal stamping provides the quality control and transparency required by defence contractors for production. The procedure can be monitored, recorded, and modified in real time. These capabilities guarantee that the parts are manufactured to the highest standards and that the metal shaping company has the supporting documentation.

Fluid Power

If you work in the fluid power sector, defined by powerful and prevalent hydraulic and pneumatic systems, you need intricate engineering and superior metal stampings to go with your fittings. Metal stamping is a reliable design option that can support supply chain longevity and product viability due to factors including:

- Moisture

- Pressure

- Temperature

- Need for long-lasting parts

These metal products can include:

- Mounting flanges

- Valve sealing components and washers

- Brackets used in severe environments

- Handles

Industrial Original Equipment Manufacturing (OEM)

When it comes to product planning and making sure the supply chain works, industrial OEM has its own set of problems. Your reputation is based on delivering goods on time and with high quality, regardless of whether you make parts sold under your own brand or those of another manufacturer. Metal stamping fits the stringent requirements of OEM by centralising the design-to-fabrication process.

Since metal stamping may drastically lower the cost per piece and increase time-to-market through technological advancements and virtual modelling, more expensive processes can profit from considering this option. Furthermore, material integrity guarantees a return on investment by extending the product's lifespan and preventing replacement.

Oil And Gas

In the oil and gas sector, mechanical failure is never an option. The tightest quality controls are necessary for this industry to ensure optimal output, efficiency, and safety. Metal stamping is an obvious choice because of its lifespan and durability due to the environmental factors present in the oil and gas business, which include:

Temperature- Light exposure

- Corrosion

- Volatile compounds

The risk of product failure in metal stamping is significantly reduced due to improvements in precision, particularly those brought about by developments in wire EDM machining. Precision metal stamping enables tighter seals that perform in the most challenging situations.

Metal stamping is used to make the following components in the oil and gas business:

- Brackets

- Handles

- washers

- Parts that seal internally

Each is built to withstand challenging and dangerous conditions.

Medical

Like the other industries, the medical sector needs things to be precise and last a long time because it directly affects people's health. When so much is at stake, your machine's metal-stamped parts must continue to work as planned. With more process control and engineering, meeting product criteria is easier.

Metal stamping is an obvious answer for accuracy and durability in medical equipment to satisfy the demands of the changing medical industry—especially when lives are involved. Compared to thermoplastics, which may offer a more affordable cost, the part's endurance will contribute to metal stamping, providing a better option over longer periods.

Automotive

Metal stamping is an industrial method frequently used to shape flat metal sheets. The procedure involves cold shaping the metal sheets into a range of forms and arrangements using specialised stamping machines and dies. A stamping press and a die are used to shape these sheets into the design that is required. To satisfy and surpass safety regulations and cut expenses, metal stamping is required for the following components:

- Chassis

- Structural elements

- Gearbox sections

These parts must be created to precise specifications. For incredibly high and reliable output, metal stamping is also needed for other elements, such as fenders and hubcaps.

What would normally be an incredibly complicated process of blanking, bending, punching, and piercing materials is made simpler by the repeatable use of dies that have been shown to meet the strict tolerance ranges needed. By using various custom-die manufacturing techniques, metal stamping producers can simplify the process and save time and cost for both their partners and end users.

Metal Bending Services In Malaysia Has Proven To Be Versatile Across Various Industries

There is much more to the art of metal stamping than meets the eye. With its accuracy, effectiveness, and affordability, it is a flexible technique that is essential to many industries. Metal stamping has proven its effectiveness in many different industries, from aerospace, which requires lightweight, robust components, to the automotive industry, which requires delicate parts.

Looking for a metal bending service in Malaysia? Try Choong Ngai Engineering

If you're looking for metal bending services in Malaysia, visit us at Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for. Call us now!

CHOONG NGAI ENGINEERING WORKS SDN BHD

is managed by a team of experienced professionals who ensures that our jobs are completed satisfactorily in a timely matter. We prioritise on our clients' needs and believe that our clients are entitled to the best services available.

QUICK LINKS

CONTACT

243A, Jalan 2A, Kampung Baru Subang, 40150 Selangor Darul Ehsan, Malaysia

Choong Ngai Engineering. All Rights Reserved. Website Designed by Heroes Of Digital.