What No One Tells About Metal Fabrication

While metal fabrication might sound like an industry that is far removed from everyday life, there are everyday applications to custom metal fabrication that you might've not noticed in your day-to-day life!

For example - have you ever taken a quick look at who manufactures the thousands of metal door knobs you see everywhere? How about the metal car door handles? Or even the metal bit of a standing fan. These parts and appliances are the result of custom metal fabrication!

It's also fair to say that a properly functioning economy is highly reliant on the metal fabrication process. In fact, our electrical systems, kitchens, vehicles, computers or any part of modern day heavy machinery would not be able to operate without the process and availability of metal fabrication.

In this article, let's explore how the metal fabrication process is done and the key benefits of metal fabrication in terms of positively impacting each and every one of our lives! That way, you'll have a better understanding of this process and how to go about contacting a metal fabrication supplier if you're seeking one for your business!

What exactly is metal fabrication?

In simple terms, metal fabrication is the process of creating parts of a machine or different structures based on raw metal materials. A typical metal fabrication process flow starts from cutting, then to burning, wielding, machining & forming. It is then finally assembled as a final product to the customer's needs.

This can include the metal bars you see on railings at your local shopping mall to industrial equipment and machinery that are capable of handling tons of materials!

Think of the diverse sectors that metal fabrication can apply to - from your everyday cutlery and tools in your toolbox to the forging or stamping machines you see in manufacturing factories!

What is the process of metal fabrication?

With its wide-ranging application from heavy industries to fast-moving consumer goods, metal fabrication requires the flexibility of being able to handle a variety of raw materials such as metal plates, wielding wire, formed metal, fittings and so on.

As custom metal fabrication is reliant on a flow of processes from wielding, machining and metal bending or forming, metal fabrication businesses will be required to employ a significant range of experts - from wielders, iron workers to blacksmiths and even a final product designer, they will turn the mentioned raw materials into the final product to be sold to the customer.

Key benefits of custom metal fabrication

While metal fabrication cover a wide scope of the industry, custom metal fabrication manufacturers or suppliers can be a cheaper alternative to small-medium scaled requirements for your metal parts.

Here are some reasons why customised metal fabrication might have an edge over their traditional counterparts:

1. Latest and up-to-date methods

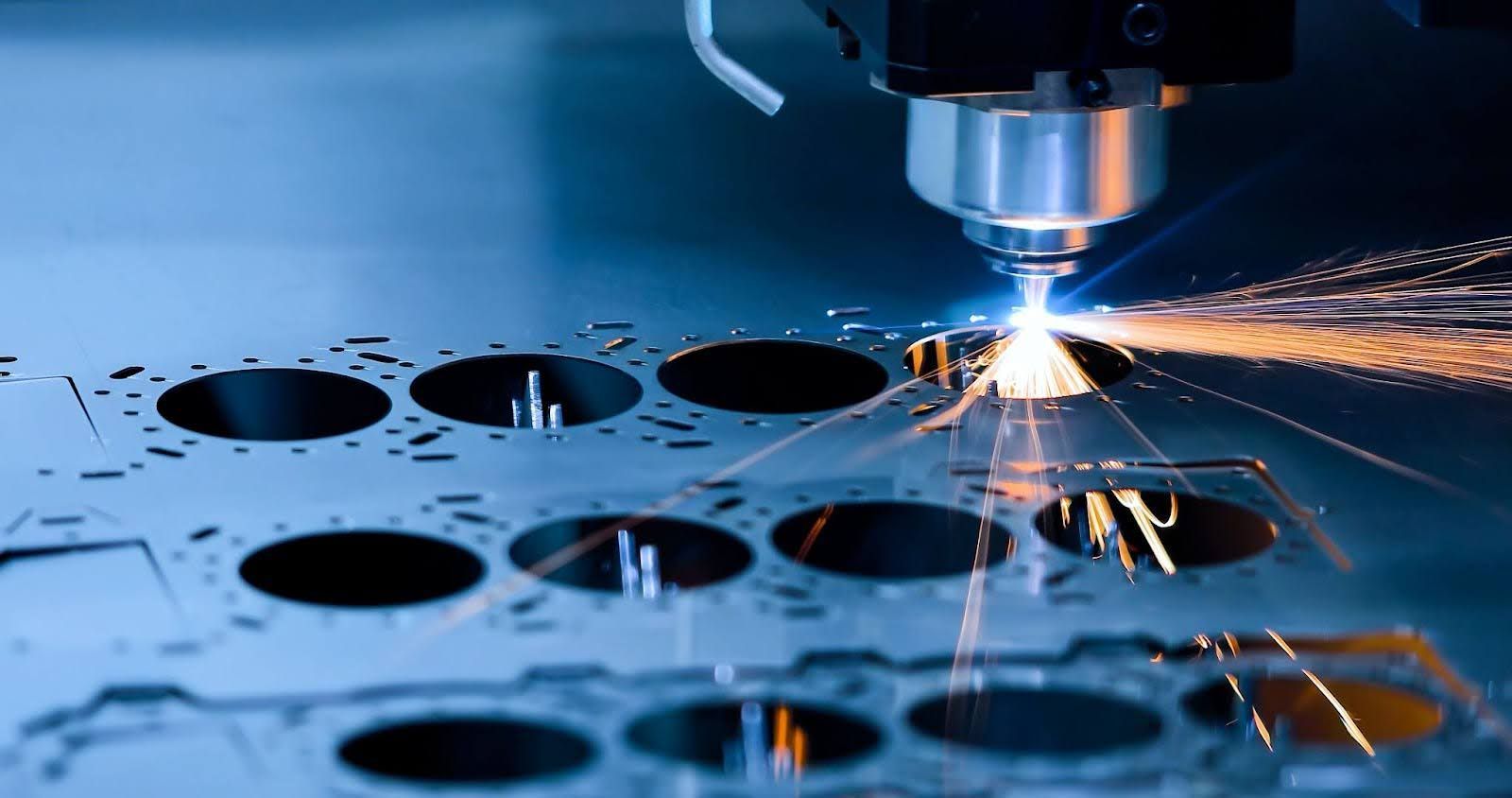

Businesses that offer custom metal fabrication products and services will usually employ advanced tools and methods to achieve the final product and results their customers desire.

They would also have access to machinery and tools that allow customisation that best fits your requirements whereas traditional metal fabrication would rely on older methods such as oxyfuel cutting.

This can include the use of waterjet cutting machinery that can be highly precise to produce a high-quality product! As compared to traditional oxyfuel cutting methods, waterjet machinery can cut just about any material, has no heat-affected zones that cause distortion or cracking, and has much higher processing tolerance. It's also a much faster method!

2. Have the flexibility to achieve your final result

For every successful project that had a successful working relationship with their metal fabrication supplier, there will be some that are unsuccessful due to not being able to get the exact form or type of metal parts that are required.

That's where custom metal fabrication businesses come in - since they specialise in customisable parts, you'll be likely to secure the parts you want, made from the materials you want and formed in the design you want!

3. Gain access to cost-effectiveness

The name of the game for custom metal fabrication businesses is the cost-effectiveness that they can offer to their customers.

In fact, custom metal fabrication businesses will often have great working connections with material providers that you can't find elsewhere. This will ensure you gain access to orders in smaller sizes and quantities that will be friendlier to the cost of your project!

They can also take advantage of trade discounts and access their material products at competitive, industrial prices! That's also partly why your costs will be driven down when you work with a custom metal fabrication business instead to secure the products you need.

Of course, doing ample amounts of due diligence and market research will ensure your prices will be the most competitive and suitable for your budget.

You can have the expertise of skilled professionals

As the custom metal fabrication sector is a highly specialised sub sector of the metal fabrication industry, you will be pleased to know that custom metal fabrication is usually carried out by highly skilled professionals!

In fact, custom fabrication machinists will definitely have years of experience - therefore, you can request for extra assistance with your project and they can lend their expertise. This could range from material selection, consultation on dimension or just to have an expert eye on the final product you're looking for.

4. Gain access to latest high-quality equipment

Where skills and expertise in metal fabrication workmanship matters heavily, the equipment used in the metal fabrication process will matter just as much. That's why custom metal fabrication companies will often have access to advanced equipment compared to traditional shops!

With these equipment, you can be assured of better quality and craftsmanship that goes into your final products. This might also result in a faster time of getting your products and materials ready for your project!

Choose a custom metal fabrication supplier that you can trust

If you're in the oil & gas, plastic manufacturing, heavy machinery or construction industry that's looking for high-quality and cost-effective metal parts with a fast turnaround time, why not give Choong Ngai Engineering a try?

With our custom metal fabrication equipment and technique, we've been servicing happy customers for over 19 years. Learn more about our services and previous projects on our website or contact us at +6012-2726971 or email your queries to choonngaiengworks@gmail.com.

CHOONG NGAI ENGINEERING WORKS SDN BHD

is managed by a team of experienced professionals who ensures that our jobs are completed satisfactorily in a timely matter. We prioritise on our clients' needs and believe that our clients are entitled to the best services available.

QUICK LINKS

CONTACT

243A, Jalan 2A, Kampung Baru Subang, 40150 Selangor Darul Ehsan, Malaysia

Choong Ngai Engineering. All Rights Reserved. Website Designed by Heroes Of Digital.