8 Uncommon Facts About Sheet Metal Fabrication

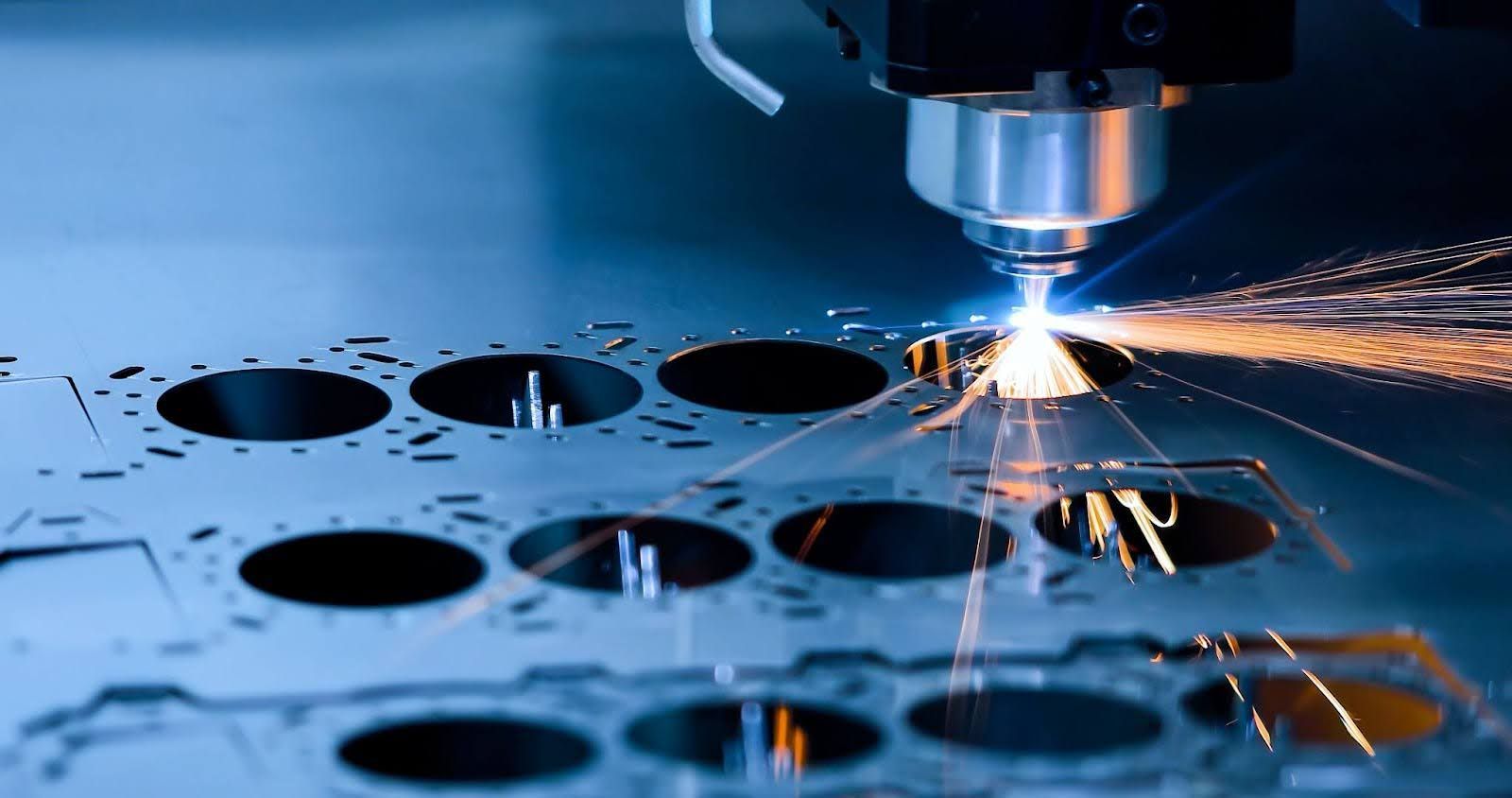

Prepare to delve into the intriguing world of sheet metal fabrication, where engineering and creativity combine to create valuable things and intricate structures. Whether you're a DIY enthusiast, a tech geek, or just someone who enjoys exciting knowledge, these unusual facts about sheet metal fabrication are about to blow your mind and inspire your creativity.

While the fundamentals of bending, cutting, and welding sheet metal may be known to you, there are a number of unusual facts that you may not be aware of. From the intriguing history of sheet metal shaping to the inventive techniques that push the limits of design, this article will reveal some of the lesser-known tidbits that will have you looking at sheet metal fabrication in a completely different manner.

Sheet Metal Has Ancient Egyptian Origins

Sheet metal was initially utilised to create beautiful jewellery by the ancient Egyptians. The Egyptians are credited with being the first to produce thin sheets of flexible, lightweight metal, even though the techniques they used were undoubtedly very different from those used in today's sheet metal fabrication companies.

First Metal Rolling Mill Sketch Way By Leonardo da Vinci

As an artist and inventor, Leonardo da Vinci was frequently ahead of his time. His contributions to the fabrication of sheet metal were no different. The first rolling mills were finally created in the 1600s, two centuries after Da Vinci initially drew his concept for one in the 1480s.

Coin manufacturing was the first business to use rolling mills. The mills produced uniform sheets that could be readily converted into coins composed of gold and silver.

Puddling Was The Initial Process

In the 18th century, metalworkers used a technique known as "puddling." Cast iron had to be heated in furnaces until it liquefied.

The main issue with this procedure was that over half of the iron was removed along with the slag. As a result, techniques created in the 19th century and later were more effective than puddling.

Puddling was a widespread technique used by metal workers to manipulate metal in the early days of the Industrial Revolution despite its inefficiency. Even the Statue of Liberty and the Eiffel Tower were built using this method.

Jean Pierre Droz Established Modern Metal Fabrication

In the late 18th and early 19th centuries, Swiss coin and metal engraver Jean Pierre Droz worked at the Paris Mint. He is renowned for creating the Napoleon coin under Napoleon Bonaparte's rule.

Droz collaborated with Englishman Matthew Boulton in the late 18th century to enhance the quality of his currency. At the beginning of the Industrial Revolution, sheet metal fabrication adopted Droz's processes to ensure uniform size and engraving.

The First Metal Punching Was In 1800s

Punching is a necessary procedure for sheet metal that will be riveted or screwed together. Since its invention in the 19th century, the technique has undergone modifications.

Manufacturers started punching metal in 1847 after bridge workers realised that putting metal components would benefit from uniform and well-placed holes.

There Are Various Finishes For Different Purposes

Different finishing procedures are applied based on how the sheet metal will be used to provide the highest quality and durability. The various finishes include the following:

- Galvanisation: Protects metal against corrosion. This method involves applying zinc to sheet metal.

- Annealing: The sheet metal undergoes heat treatment, which enhances workability.

- Anodising: A technique that involves applying aluminium to metal to preserve it from wear and tear.

- Tinning: Tinning is used for food cans and other metals that come into contact with food. It stops metal from oxidising.

- Tempering: Metal is heated and cooled during tempering to strengthen its durability.

Sheet Metal For Roofing Has Different Materials

While aluminium and steel are common metal roofing materials, other popular metals used in roofing production include the following:

- Copper

- Zinc

- Iron

- Lead

Manufacturing businesses select from various materials according to their intended aesthetic, weight, and degree of durability. Each metal contributes its unique features to the final roofing product.

Sheet Metal Has Various Thickness

While "sheet metal" may conjure images of paper-thin metal, a variety of thicknesses are fabricated based on the intended usage.

The standard thickness of sheet metal in today's fabrication companies ranges from 1.5 mm to 6 mm. In general, sheet metal is not thicker than 14 mm.

Most applications require thin, flexible sheet metal that is also durable. Metal thicker or thinner than the specifications mentioned above will be either too delicate to endure fabrication and use or too thick to manipulate.

A Sheet Metal Is A Humble Element That Has Withstood The Test Of Time

That concludes this quick tour of the beautiful world of sheet metal fabrication. Sheet metal production is undoubtedly a craft of surprises, from the surprising historical connections to the astounding powers of modern machinery.

Remember these unique facts the next time you see a sleek car body, a perfectly constructed sculpture, or even the gleaming towers that define our city landscapes. They are evidence of the commitment, ingenuity, and pure creativity that go into each bend, cut, and weld.

Looking for a quality sheet metal fabrication company in Malaysia? Choose Choong Ngai Engineering!

So, if you're looking for

sheet metal fabrication in Malaysia, visit us at

Choong Ngai Engineering today to speak to our experts. We at Choong Ngai Engineering have years of experience and knowledge to answer your doubts or concerns, and we ensure to provide you with the quality solution you're looking for.

Call us now!

CHOONG NGAI ENGINEERING WORKS SDN BHD

is managed by a team of experienced professionals who ensures that our jobs are completed satisfactorily in a timely matter. We prioritise on our clients' needs and believe that our clients are entitled to the best services available.

QUICK LINKS

CONTACT

243A, Jalan 2A, Kampung Baru Subang, 40150 Selangor Darul Ehsan, Malaysia

Choong Ngai Engineering. All Rights Reserved. Website Designed by Heroes Of Digital.