What is The Different Between Turning And Milling Services?

Turning and milling both are conventional machining operations; however, each of them has different capabilities and thus is suitable for fabricating different features by removing material from a work piece.

In this article, we'll explore the different purposes that turning and milling serves when it comes to fabrication, their differences and their varying applications. We'll also discuss where to find one of the best turning and milling services company in Malaysia!

What is turning and milling?

Turning is extensively used for generating cylindrical or conical surfaces. Here the primary blank (pre-machined raw material) can be of any shape (based on available fixture and machine capability). It employs a single point turning tool to shear of a thin layer of material in the form of continuous or discontinuous chips. This operation is performed on a well-known and versatile machine tool, called lathe. Based on the machined features, turning can be sun-grouped as straight turning, taper turning, internal turning, stepped turning, etc. However in all cases generated surface is either cylindrical or conical.

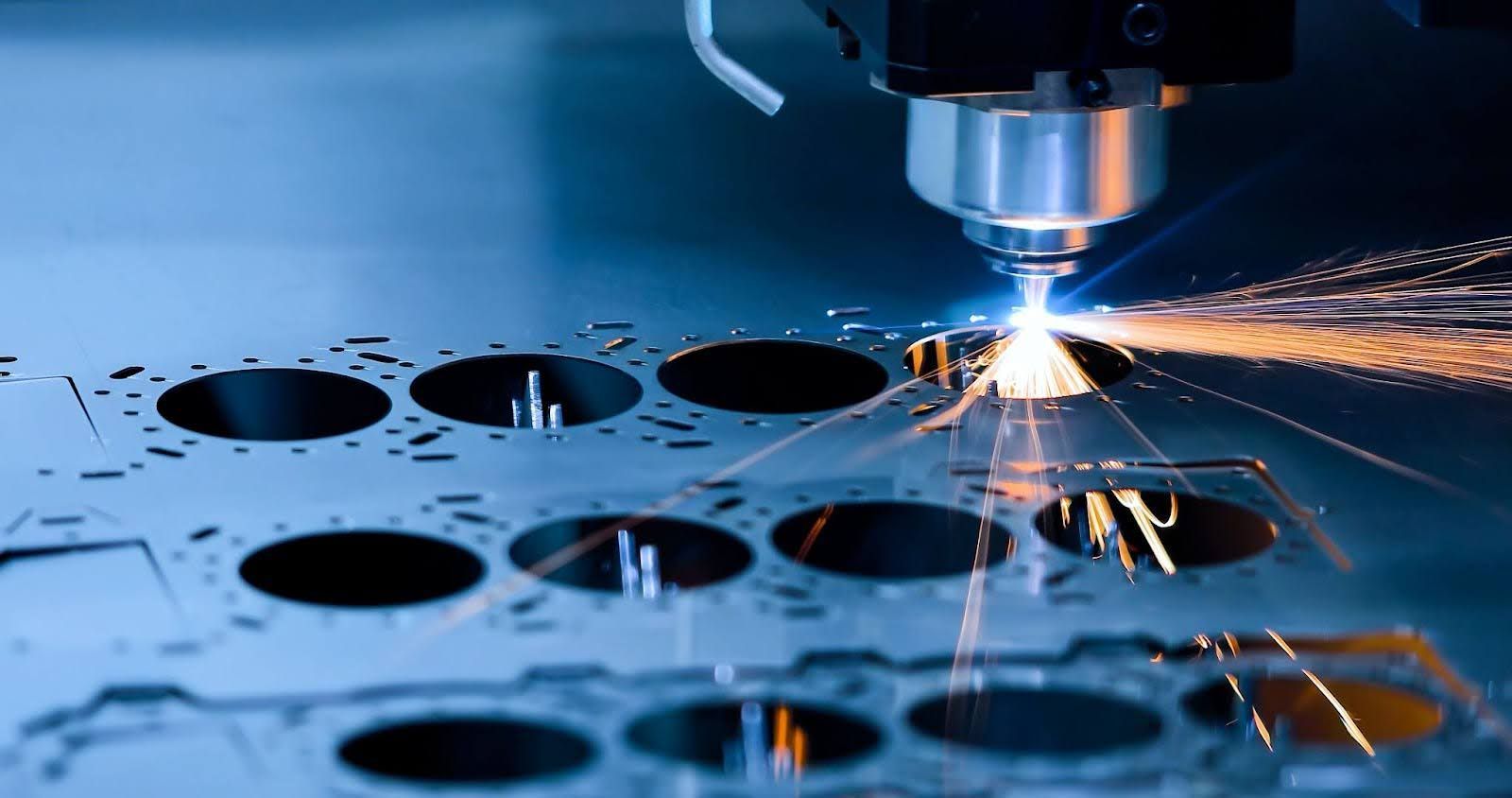

Although milling is also a machining operation like turning, its process technique, capability and shape of generated feature differ from turning. While turning produces cylindrical or conical surface, milling is useful for generating flat or sculptured surfaces. It employs a multi-point cutting tool that may contain 2 – 150 cutting edges. Thus milling is a faster process that results in higher productivity. The operation is performed on a milling machine that can have either a horizontal spindle or vertical spindle. Based on generated features and technique, milling can also be sub-grouped as face milling, side milling, end milling, and etc.

What are the differences between turning and milling?

| Turning | Milling |

|---|---|

| Turning is used to produce cylindrical or conical surfaces. | Milling is used to produce flat or sculptured surfaces. |

| It is performed in lathe machine tool. | Milling is performed on a milling machine. |

| Turning employs a single point cutter. Cutter contains only one main cutting edge. | Milling employs a multi-point cutter. Cutter contains more than one cutting edge. |

| Cutting motion is imparted by rotating the workpiece. | Cutting motion is imparted by rotating the cutter. |

| Feed motion is imparted by moving the cutter against the workpiece. | Feed motion is imparted by moving the workpiece against the cutter. |

| Turning is usually a continuous cutting operation. | Milling is usually an intermittent cutting operation. |

| Turning produces continuous chips unless the condition is unfavourable. | Milling inherently produces discontinuous chips. |

| Material removal rate is low due to single point cutter. | It provides high MRR and thus productivity increases. |

What are the different ways of turning and milling are applied when machining a workpiece?

Generated surface and features: Turning is predominantly used for generating cylindrical or conical surfaces irrespective of the shape of raw material. Any feature generated by this process must be rotationally symmetric. Typically it can be employed for fabricating axisymmetric parts like cylindrical or conical shafts, stepped shafts, tapered objects, increasing diameter of internal holes (cannot originate a hole), cutting cylindrical groves, etc. Contrary to this, milling can be employed to generate flat surface of any orientation as well as contour surfaces. Features like slots, channels, key holes, pockets, walls, fins, webs, etc. are commonly encountered in milling.

Machine tools employed for operations: Turning is performed in a versatile machine tool called lathe. This is primarily horizontal axis machine tool (spindle is horizontal); however, vertical axis lathe is also available, especially on a table top. Milling is carried out in a milling machine, which can have either a vertical axis or horizontal axis (both are common).

Single point and multi-point cutter: A turning operation is performed using a single point cutter, called SPTT (single point turning tool). Hence, it has only one main cutting edge that can actively participate in shearing or removing of materials. Contrary to this, a milling cutter may contain 2 – 150 cutting edges, sometimes even more. As it is one multi-point cutter, more than one cutting edge simultaneously participate in shearing or removing of materials.

Looking for turning and milling services? Try Choong Ngai Engineering

With Choong Ngai Engineering's veteran technicians and engineers, we can provide start-to-end turning and milling services for your business.

Most importantly, we'll work alongside you and your team to understand and define your exact requirements, and this process ensures that we provide the best solution to your unique requirements.

Learn more about our services and previous projects on our website at https://www.choongngaiengineering.com/ or contact us at choonngaiengworks@gmail.com

CHOONG NGAI ENGINEERING WORKS SDN BHD

is managed by a team of experienced professionals who ensures that our jobs are completed satisfactorily in a timely matter. We prioritise on our clients' needs and believe that our clients are entitled to the best services available.

QUICK LINKS

CONTACT

243A, Jalan 2A, Kampung Baru Subang, 40150 Selangor Darul Ehsan, Malaysia

Choong Ngai Engineering. All Rights Reserved. Website Designed by Heroes Of Digital.