Types of Sheet Metal Fabrication That You Should Know

In the early days of metal fabrication, it was common to melt copper and subsequently process it to make various early-age objects. Next comes bronze that was used to make armor, coins, and weapons shifting towards iron-age, followed by cast-iron.

With technology ever-evolving and with the help of the industrial revolution, structural metal fabrication or steel as well as sheet metal fabrication has overtaken the construction industry by storm and is becoming the norm today.

Uses Of Structural Steel Fabrication

The use of structural metal or steel fabrication or sheet metal fabrication has expanded significantly in the industry of construction and infrastructure. In fact, structural steel is a top-quality material that is trusted and depended on solely due to its properties. Some of the industries that utilise structural steel include:

1. Commercial buildings of varying sizes

The low weight of structural metal such as steel and its excessive strength creates it perfect for utilization in constructing large structures.

Today's high-rise buildings are frequently built from concrete and reinforced steel, and the highrises are nearly always made up of a steel frame.

Another advantage of utilizing structural steel during these huge buildings is the quickness of construction that it provides. If you have a productive team, structural metal such as steel can be fabricated easily.

2. Industrial structures

When developing industrial structures, structural steel is regarded as the ideal material. The reasons for this are many such as the strength, value, and durability components.

Structural steel offers a lot of strength and is excellent for the buildings that require durability. Additionally, structural steel is among the strongest load-carrying material in construction as well as carrying great balance and weather resistance.

3. Parking areas

Structural steel is a perfect material for constructing structures such as garage areas for similar causes as large structures. Its benefits include a low construction period, lower construction value, and long-term durability.

The light and portable attribute of structural steel make it the top material to be utilized in parking areas.

4. Bridges

Among the typical uses of structural steel fabrication is building bridges. The excellent durability to the weight proportion of structural steel is an excellent advantage for these unique structures. Also, its standard of durability makes sure that it will bear the weight of vehicles confidently.

Types Of Metal Fabrication Processes

The following are different types of metal fabrication processes that occur after the initial stages of project planning:

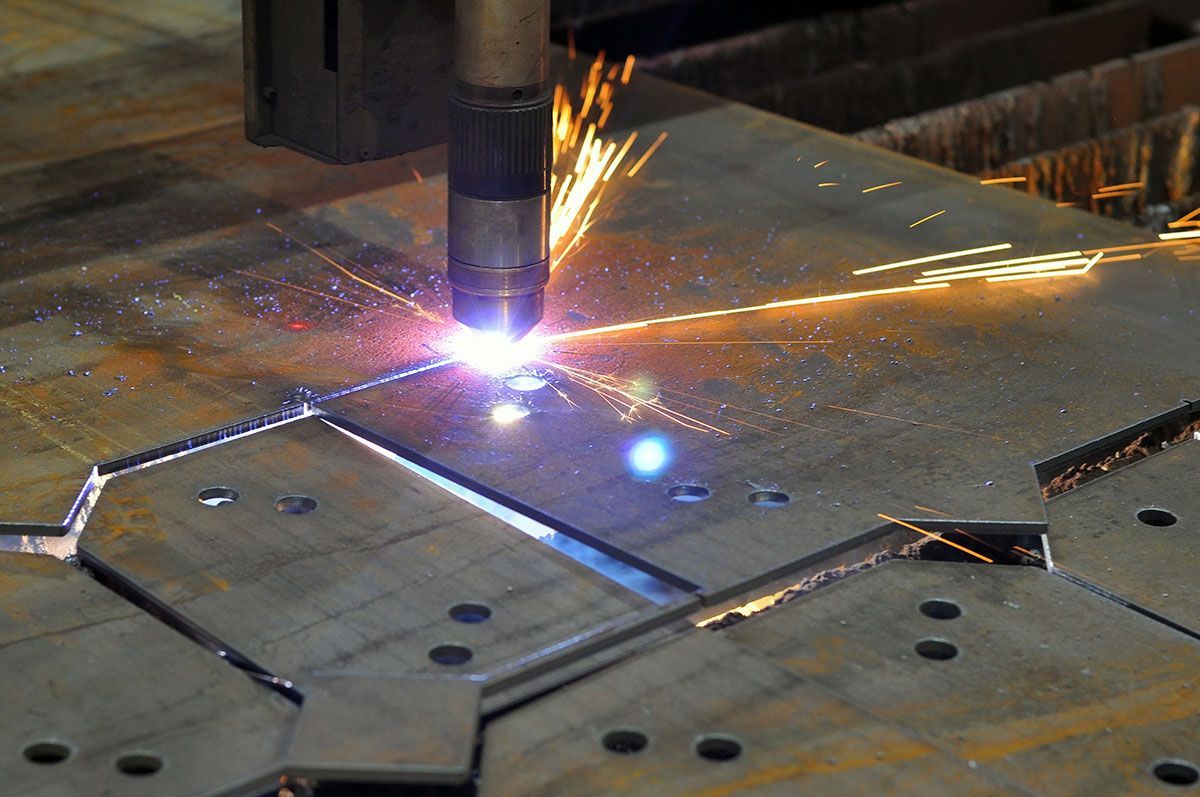

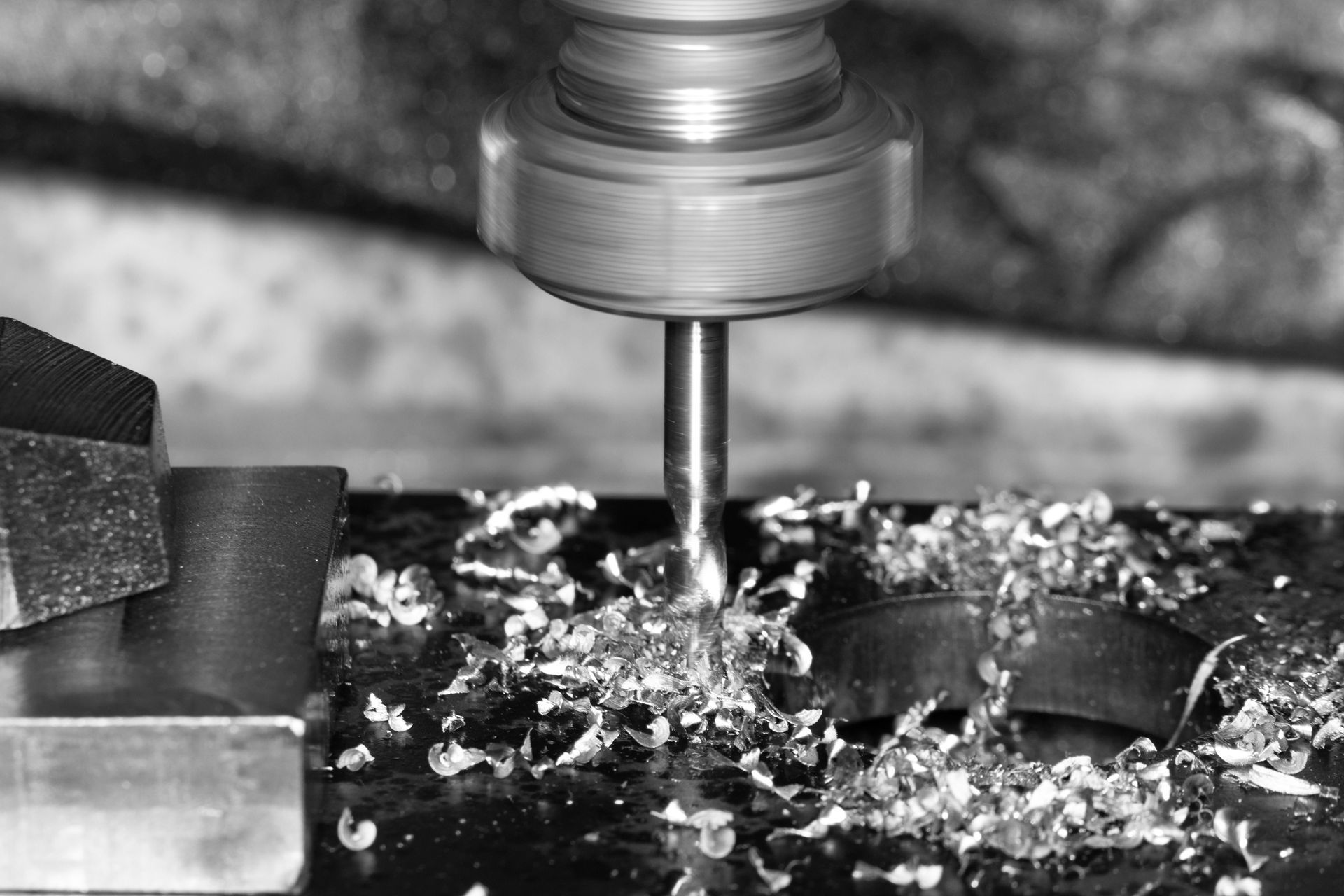

1. Cutting

This is the first stage of any fabrication process. Steel is first cut using a saw, water jets, plasma torches or lasers. There are other techniques used for cutting, such as numerical control, chiseling, and shearing.

These tasks can be performed by CNC (computer numerical control) or power tools. Cutting is frequently the first step in a fabrication project. It does not always have to be a sheet of metal; sometimes, pre-shaped metals like bars can be cut.

Die-cutting is a process that uses a die to cut material. Rotary die cutting employs a cylindrical die attached to a rotary press, flatbed die cutting uses a press to cut shapes out of thicker metals, and digital die-cutting involves computer-controlled lasers and blades.

2. Casting

Casting is the process by which molten metal is poured into a die to cool and harden over time to create a product. It is also a money saver because it fast-tracks a series of processes that might be used to make the same part (i.e. cutting, folding, stamping).

A permanent mold casting is made from a steel or cast iron. The molten metal is poured, cooled, and removed. A sand casting will break away to reveal the part made. During die casting, metal is poured into a die and forced to maintain shape through applied pressure.

3. Welding

Welding involves attaching two pieces of metal to form a separate steel section or build a large structure. There are different types of welding processes which are used based on the metal and overall design of the structure.

This is accomplished through a combination of heat and pressure. The most common process is Metal Inert Gas (MIG) or Gas Metal Arc Welding (GMAW), which applies a shielded gas along a wire electrode with a constant and direct power source.

4. Stamping

Stamping uses a press to create indentations and raises metal in order to create specific shapes. In this process, the die is shaped in a way that there is a raised portion of the material.

Stamping helps to convert the flat metal sheeting into various shapes. Stamping uses the die that causes the material to be raised instead of penetrating the metal. For instance, metal stamping is used on coins where you get to see the words, currency amounts, and face of presidents stamped on the coin.

5. Folding

Folding or bending is done by a process called press brake. Steel needs to be bent to create certain steel sections. This technique is used to coin or air bend metal sheet into form. The press brake technique has a set of dies which pinches the metal to form a crease.

This is a complicated process meant to bend metal at different angles and commonly involves a brake press to shape a sheet. Products such as shelf brackets or computer equipment are produced via this method.

6. Shearing

Shearing is the process of making a long cut on a piece of metal. It is, in effect, just like the action of one of those paper cutters with the long chop-handle. This is done on sheet metal.

During the shearing process, an upper blade and a lower blade are forced past each other with the space between them determined by a required offset.

Choose a structural metal fabricator or sheet metal fabrication supplier you can trust

If your business is looking for high-quality and cost-effective metal parts with a fast turnaround time, why not give Choong Ngai Engineering a try?

With our custom metal fabrication equipment and technique, we've been servicing happy customers for over 20 years. Learn more about our services and previous projects on our website or contact us at choonngaiengworks@gmail.com.